PLEASE NOTE: This is the Archived Sexyloops Board from years 2004-2013.

Our active community is here: https://www.sexyloops.co.uk/theboard/

Our active community is here: https://www.sexyloops.co.uk/theboard/

Harmonic Oscillator

- Paul Arden

- Fly God 2010

- Posts: 23925

- Joined: Sat Jul 26, 2003 10:35 am

- Location: Travelling

- Contact:

-

gordonjudd

- IB3 Member Level 1

- Posts: 2214

- Joined: Mon Jul 10, 2006 12:14 am

- Location: California

- Contact:

Seems as though the torque required would be somewhat higher depending on where the IC was for that part of the cast or am I missing something?

Bob,

As I mentioned to you before the line does not have a MOI since it is not rotating so this is just a rough approximation since we are assuming that the torque required is:

T=angular acceleration*MOI of reel,rod, and line.

Thus this torque is just a ball park estimate of the actual torque, but I wanted to show that it would be much smaller than the 80-100 N-m value that Merlin estimated for a distance cast in a less "heroic" fishing cast.

The "equivalent" MOI of the line was taken to be its mass*(distance from elbow to tip of rod).^2 at MRF since that is when the deceleration is applied for most casts.

I used the elbow as the rotation center at that point (as Merlin did in his calculation) to get an estimate for what kind of force would be applied to the hand that would result from the torque being applied by the elbow.

Now that you raised this point, I now realize that the MOI of the forearm should have been included in that calculation. That probably has a much larger MOI than the rod or reel since its mass is so much larger. Assuming the mass of the forearm is 3.2 kg, its its MOI (about the elbow) would be 1/3*mass*.4.^2.=.32 kg-m.^2

That would increase the torque required to decelerate the arm, reel, rod, and line mass to around 40 N-m although the portion of that required to decelerate just the reel, rod, and line mass would be only be 12 N-m as calculated before.

Gordy

"Flyfishing: 200 years of tradition unencumbered by progress." Ralph Cutter

- grunde

- Master of The Kettle

- Posts: 1462

- Joined: Thu Sep 09, 2004 5:48 pm

- Location: Drammen, Norway

- Contact:

Guys,

You can not ignore the "line pull" at the tip end of the rod during the stop when estimating the torque.

I (like Server Sadik) believe that (at least) the first part of the rapid decceleration is caused by the unloading rod, and not by an active stop by the caster.

I think I've said it before, I usually try to "relax" the stop...

Cheers,

Grunde

You can not ignore the "line pull" at the tip end of the rod during the stop when estimating the torque.

I (like Server Sadik) believe that (at least) the first part of the rapid decceleration is caused by the unloading rod, and not by an active stop by the caster.

I think I've said it before, I usually try to "relax" the stop...

Cheers,

Grunde

"Essentially, all models are wrong, but some are useful."

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

-

gordonjudd

- IB3 Member Level 1

- Posts: 2214

- Joined: Mon Jul 10, 2006 12:14 am

- Location: California

- Contact:

You can not ignore the "line pull" at the tip end of the rod during the stop when estimating the torque.

Grunde,

Did you mean you can ignore the mass of the line in determining the torque required to stop the rod?

Your point about when the mass of the line should be decoupled from the reel, rod, line system is well taken, and points out the pitfalls of using rigid body mechanics to look at flexible, distributed masses.

The line is not going to be immediately impacted by the deceleration torque applied at rod butt. However, from MRF to RSP1 the line is still being accelerated by the unbending of the rod, and in your model I still include the line mass to get the total mass (mo + m_line) that is used to see how the deflection of the rod varies as it unloads.

I (like Server Sadik) believe that (at least) the first part of the rapid deceleration is caused by the unloading rod, and not by an active stop by the caster.

As you have pointed out previously the deflection vs time profile from MRF to RSP1 is dominated by the deceleration rate, not by the much slower lower loaded frequency of an unforced spring/mass system.

Thus from using your model, I would expect the deceleration applied by the caster would be a much bigger effect on the shape of the unloading deflection curve than its "natural" unloading frequency (even the initial rate), and that the mass value used in your model from MRF to RSP1 should still include the line mass.

After RSP1 Merlin and I assume the line is decoupled from the spring/mass system. Consequently after RSP1 the mass would revert back to just mo of the spring and a much higher damping coefficient (.9 in this case) is used to get a good match to the deflection curve during counterflex as shown below.

Thanks for pointing out that the torque estimate required to stop the rod is primarily a function of the MOI of the rod and reel. I agree that the mass impact of the line does not impact the torque required to stop the rod.

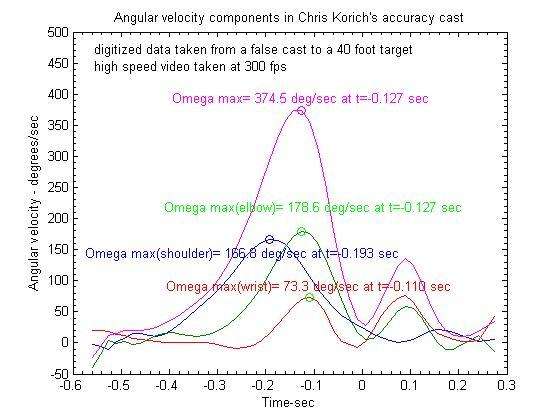

Another factor to consider in this torque application problem is that different casters are going to combine the use of different joints to stop the rod. As you can see from this plot of Chris Korich's accuracy cast he primarily uses his elbow to rotate the rod near MRF, but there are also contribution coming from the shoulder and wrist as well.

Thus my torque estimate should be divided among the different joints, and not just attributed to the elbow, and that division would be impacted by the caster's style. Taking all of that into account, you can see my 12 N-m elbow torque calculation was a gross simplification.

Gordy

"Flyfishing: 200 years of tradition unencumbered by progress." Ralph Cutter

Bernd,

For a distance cast, there is no adaptation to the rod: the caster just applies as much power as he can. His goal is then to find the best tackle for his casting style. For fishing cast, the question remains open. We cannot tell today if there is a prefered way for adapting to the tackle.

Grunde

The beginning of rod unloading can happen before deceleration if the rod is fast, but this may represents up to 5% of the deceleration. Peanuts, you can check it with your own model.

Merlin

For a distance cast, there is no adaptation to the rod: the caster just applies as much power as he can. His goal is then to find the best tackle for his casting style. For fishing cast, the question remains open. We cannot tell today if there is a prefered way for adapting to the tackle.

Grunde

The beginning of rod unloading can happen before deceleration if the rod is fast, but this may represents up to 5% of the deceleration. Peanuts, you can check it with your own model.

Merlin

Fly rods are like women, they wont´play if they're maltreated.

Charles Ritz, A Flyfisher's Life

Charles Ritz, A Flyfisher's Life

- Bobinmich

- IB3 Member Level 1

- Posts: 606

- Joined: Fri Sep 14, 2007 4:09 pm

- Location: Rochester, MI

- Contact:

Gordy,

I have long been searching for an illusive factor I like to call "handle metrics" when it comes to analyzing casting and the effects of rod and reel properties on same. While different muscle groups are used to stop different body parts in the cast, IMHO the caster is most sensitive to what he feels in his hand. If that is true, then how you estimated torque was right on. While you must either know or estimate an IC to calculate the required torque and the MOI of the rod/reel (not line as it is decoupled at this point as you said), to get the torque you are feeling in your hand you need not include the MOI of other body parts. I think your estimate is a good one.

Since I used to do a lot of night fishing, I guess I am oversensitive to using this feeling in your hand to time my casts but I am convinced it plays a major role in most casters tool box. It is nice to see tools being developed that might lead to quantifying what goes on at the hand/rod interface. I have been continuing to work on piecewise linear solutions but I have reached a snag in they do not handle the inertial properties of the rod as well as does the SHO. I also am bogged down in determining true spring rates for the rod at different angles of load application. I had hoped a simple exponential equation would have handled it but it appears I will have to write in logic for a look-up table.

I think a gap remains between what is needed for engineering and understanding casting and what "Joe Blow" might need to help him pick a rod. As I said before, the two schools are joined at the hip but we need to make them learn to talk to each other. How do we make the "stiff" and "slow," that Joe might recognize, relate to real design parameters that a rod builder can use.

But the journey continues, doesn't it.

Bob

I have long been searching for an illusive factor I like to call "handle metrics" when it comes to analyzing casting and the effects of rod and reel properties on same. While different muscle groups are used to stop different body parts in the cast, IMHO the caster is most sensitive to what he feels in his hand. If that is true, then how you estimated torque was right on. While you must either know or estimate an IC to calculate the required torque and the MOI of the rod/reel (not line as it is decoupled at this point as you said), to get the torque you are feeling in your hand you need not include the MOI of other body parts. I think your estimate is a good one.

Since I used to do a lot of night fishing, I guess I am oversensitive to using this feeling in your hand to time my casts but I am convinced it plays a major role in most casters tool box. It is nice to see tools being developed that might lead to quantifying what goes on at the hand/rod interface. I have been continuing to work on piecewise linear solutions but I have reached a snag in they do not handle the inertial properties of the rod as well as does the SHO. I also am bogged down in determining true spring rates for the rod at different angles of load application. I had hoped a simple exponential equation would have handled it but it appears I will have to write in logic for a look-up table.

I think a gap remains between what is needed for engineering and understanding casting and what "Joe Blow" might need to help him pick a rod. As I said before, the two schools are joined at the hip but we need to make them learn to talk to each other. How do we make the "stiff" and "slow," that Joe might recognize, relate to real design parameters that a rod builder can use.

But the journey continues, doesn't it.

Bob

Bob Bolton

www.HATofMichigan.org

www.HATofMichigan.org

- grunde

- Master of The Kettle

- Posts: 1462

- Joined: Thu Sep 09, 2004 5:48 pm

- Location: Drammen, Norway

- Contact:

gordonjudd wrote:You can not ignore the "line pull" at the tip end of the rod during the stop when estimating the torque.

...

Your point about when the mass of the line should be decoupled from the reel, rod, line system is well taken, and points out the pitfalls of using rigid body mechanics to look at flexible, distributed masses.

I don't get the first part of that sentence, I do however agree with the last part: You can't uncritically use rigid body mechanics.

Thanks for pointing out that the torque estimate required to stop the rod is primarily a function of the MOI of the rod and reel. I agree that the mass impact of the line does not impact the torque required to stop the rod.

This is exactly _not_ what I'm saying

The fact that the rod is bended and attached to a line while unloading is very important...

Merlin wrote: The beginning of rod unloading can happen before deceleration if the rod is fast, but this may represents up to 5% of the deceleration. Peanuts, you can check it with your own model.

I'm fully aware of the fact that one can reach max rod bend before, after, or at max angular velocity (depending on rod parameters and the input from the caster). But that is not what I'm talking about.

One can actually argue that the torque from the caster on the rod is in the forward direction as long as the rod but is bended backwards (I've measured this, and it passes through 0 roughly halfway into the unload (think I've discussed "the load shift" here at some point?)).

Guess I should make a drawing to illustrate my point, I'll maybe do so later. But for now imagine the following taught experiment: You are casting some line length and you have an analyzer attached to the rod but:

1) You are casting a broomstick, and exactly at max angular velocity (MAV) you simply drop the rod. What happens to the angular velocity (measured at the but) of the rod?

For the broomstick it simply remains constant, and at least for a while it's not at al affected by the attached fly line...

2) You are casting a flexible fly rod. And at MAV the rod is also at it's maximum load (bend), and we simply repeat the exercise above.

This time the angular velocity will decrease rapidly because the rod is unloading. This is actually an experiment someone with a fast camera can go out and perform

Disclaimer:

I should probably have a closer look at your torque calculations to fully understand your assumptions (like the damping factor mentioned above) and results...

Cheers,

Grunde

"Essentially, all models are wrong, but some are useful."

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

-

Eugene Moore

- IB3 Member Level 1

- Posts: 93

- Joined: Wed Jul 06, 2011 1:27 am

- Location: Missouri

- Contact:

The fly line is definitely a portion of the forward cast during the acceleration phase. The line mass changes based on time and loop shape from the backcast. How much of this is added is dependent on the timing of the acceleration. Ideally the max acceleration of the rod should occur with the max line mass during the un-coil.

This will couple the wave energy of both the rod and the line producing more rod bend and stored energy. At decel we only have to handle the rod mass as the line uncouples.

This will couple the wave energy of both the rod and the line producing more rod bend and stored energy. At decel we only have to handle the rod mass as the line uncouples.

Eugene Moore

-

gordonjudd

- IB3 Member Level 1

- Posts: 2214

- Joined: Mon Jul 10, 2006 12:14 am

- Location: California

- Contact:

2) You are casting a flexible fly rod. And at MAV the rod is also at it's maximum load (bend), and we simply repeat the exercise above.

This time the angular velocity will decrease rapidly because the rod is unloading. This is actually an experiment someone with a fast camera can go out and perform

Grunde,

I will try that experiment when I get home next week.

Is there anyway you can use your model to show what happens to the rod bend when you drop a flexible rod?

Thanks for clarifying what I thought you were talking about. I totally misunderstood the point you were making.

With the broomstick the angular deceleration resulting from applying a reversing torque applied at the grip would slow down the rod tip, but not affect the line velocity since you cannot push a string. In that case I would think the torque required to stop the rod would just depend on the MOI of the rod and reel, since the mass of the line would not be affected by the stop.

It is nice to have a physicist's insight into this problem as your drop the rod exercise is not something I would have come up with.

I (like Server Sadik) believe that (at least) the first part of the rapid deceleration is caused by the unloading rod, and not by an active stop by the caster.

From what I have seen using your model, I do not understand what you meant by that comment either.

Do you think that the unloading time of the rod is primarily dependent on the deceleration applied at the butt, or do you expect it has more to do with the loaded frequency of the spring/mass system and is somewhat independent of the applied forcing function?

Gordy

"Flyfishing: 200 years of tradition unencumbered by progress." Ralph Cutter

One can actually argue that the torque from the caster on the rod is in the forward direction as long as the rod but is bended backwards (I've measured this, and it passes through 0 roughly halfway into the unload (think I've discussed "the load shift" here at some point?)).

Grunde

This seems to me possible after line launch, as the rod is going to MCF and back to RSP. We tend to have a loose grip at this stage of the cast, and a casting analyzer can pick up a forward motion of the butt as the rod bends forward, then backwards after line launch.

You may take an analogy when the rod is unloading in the forward direction, and it would mean that there is some “contribution” from the unloading to ease the torque on the caster’s hand. I would agree that to be possible if our grip was loose at that time (the example with the drop of the rod), but this might well not be the case as we squeeze it to decelerate the butt. At that period of time, we are close to maximum power. We do force the rod to come back to RSP faster than it would naturally do. When we are close to RSP, we ease the grip most of the time.

When looking at SHO models (yours or mine), I can’t see that type of contribution. If it does exist in the real world, it means that we are not casting robots, with rigid segments, but that there is another degree of freedom that we do not take in account into the models (e.g. our joints are elastic).

If you have some evidence of this phenomenon, thanks to post it. For the current SHO models, this is not visible at all.

Merlin

Fly rods are like women, they wont´play if they're maltreated.

Charles Ritz, A Flyfisher's Life

Charles Ritz, A Flyfisher's Life

- grunde

- Master of The Kettle

- Posts: 1462

- Joined: Thu Sep 09, 2004 5:48 pm

- Location: Drammen, Norway

- Contact:

Merlin & Gordy,

I don't have the time to answer all your questions before (maybe) sometime next week, sorry.

But for now I have a couple of points/question and a small brain teaser

The fact that a simple linear model (Bric-Spring-Car BSC), consisting of a point mass attached to a mass-less linear spring pulled by a "car" (of unknown/unspecified properties) does not fully describe the complex motion of a tapered flexible beam in 2D should come as no surprise... (It's still a useful model, but be aware of it's limitations.)

In the BSC-model what is the direction of the force from the car on the spring during "the stop"? And what is the direction of the force on the car from the spring? This is actually the basis for my earlier short-/long-stop discussion.

Can one measure the torque during the casting stroke? Yes! With a strain gauge on the butt section close to the cork or with image analysis like I have done. I think this data (the curves are in my "haul talk" slides) is the prof that there is _no_ monstrous backward "stopping" torque from the casters wrist during the stop. I think the maximum reverse torque comes when the rod approaches max counter flex (during/after loop formation).

During the stop the rod changes shape. I think I've mentioned this change in rod bend shape during the stop before? Jason B. (and I) call this "the load shift". And assuming the same bend-shape during the stop as during static loading is (probably) the erroneous assumption behind the Perkins/Richards 50%/50% speed from rotation/spring result...

The brain teaser:

http://www.lmm.jussieu.fr/spaghetti/movies-3-exp.html

Have a nice weekend! I'll try to catch a fish or two :pirate

Cheers,

Grunde

I don't have the time to answer all your questions before (maybe) sometime next week, sorry.

But for now I have a couple of points/question and a small brain teaser

The fact that a simple linear model (Bric-Spring-Car BSC), consisting of a point mass attached to a mass-less linear spring pulled by a "car" (of unknown/unspecified properties) does not fully describe the complex motion of a tapered flexible beam in 2D should come as no surprise... (It's still a useful model, but be aware of it's limitations.)

In the BSC-model what is the direction of the force from the car on the spring during "the stop"? And what is the direction of the force on the car from the spring? This is actually the basis for my earlier short-/long-stop discussion.

Can one measure the torque during the casting stroke? Yes! With a strain gauge on the butt section close to the cork or with image analysis like I have done. I think this data (the curves are in my "haul talk" slides) is the prof that there is _no_ monstrous backward "stopping" torque from the casters wrist during the stop. I think the maximum reverse torque comes when the rod approaches max counter flex (during/after loop formation).

During the stop the rod changes shape. I think I've mentioned this change in rod bend shape during the stop before? Jason B. (and I) call this "the load shift". And assuming the same bend-shape during the stop as during static loading is (probably) the erroneous assumption behind the Perkins/Richards 50%/50% speed from rotation/spring result...

The brain teaser:

http://www.lmm.jussieu.fr/spaghetti/movies-3-exp.html

Have a nice weekend! I'll try to catch a fish or two :pirate

Cheers,

Grunde

"Essentially, all models are wrong, but some are useful."

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

- Bobinmich

- IB3 Member Level 1

- Posts: 606

- Joined: Fri Sep 14, 2007 4:09 pm

- Location: Rochester, MI

- Contact:

Seems to me I remember that the angular velocity peak from an analyzer peaks before RSP and is headed down fast at RSP. That all seems to make sense as the line accelerates to RSP and the force to accelerate it (from the rod unloading) must have a reactionary componant in the reverse direction. This would have to be resisted by the caster and the inertia of the reel and rod handle. Most of my models tend to show something fishy going on there that is rather complex. I'll work on it a bit.

Bob

Bob

Bob Bolton

www.HATofMichigan.org

www.HATofMichigan.org

-

gordonjudd

- IB3 Member Level 1

- Posts: 2214

- Joined: Mon Jul 10, 2006 12:14 am

- Location: California

- Contact:

Can one measure the torque during the casting stroke? Yes! With a strain gauge on the butt section close to the cork or with image analysis like I have done. I think this data (the curves are in my "haul talk" slides) is the proof that there is _no_ monstrous backward "stopping" torque from the casters wrist during the stop. I think the maximum reverse torque comes when the rod approaches max counter flex (during/after loop formation).

Grunde,

I do not see the relationship you are seeing in how the bending stress in the rod is related to the torque being applied at the butt.

In order to stop the rotation of a rigid rod rotating in the clockwise direction about some axis you would need to apply a counterclockwise torque that would induce a negative angular acceleration value that would bring the rod rotation to an end. The larger that negative angular acceleration value, the quicker the angular velocity would go to zero. In the simple case where the deceleration is constant (such as in Mathias' cast with the Paradigm rod) t_stop=omega_max/(angular deceleration).

Just because the rod is flexible I do not see why that would change the T=MOI*angular_acceleration relationship involved in stopping the rotation of the nominally stiff butt end of the rod. It would seem to me that to stop the rotation of the rod you would need to apply an immediate and sizable negative torque to the different joints being used to stop the rotation of the butt of the rod.

I can see that it would take more torque to apply the deflection force from the spring in the rod to the line since the peak force from a flexible rod is nearly twice the value you would expect for a stiff rod. I now see that the torque required to move the accelerating force on the the line would remain positive as long as the rod was bent and was supplying a positive accelerating force on the line.

Thus it would appear there are two torque components involved. A sizable negative torque to stop the rotation of the rod over a short time interval, and a varying positive torque required to continue to do work on the line as the rod unloads.

The way you would measure the resulting negative angular acceleration applied to stop the rod would be done by computing the derivative of the rotational angular velocity of the rod butt. Would the torque required to acceleration the line just depend on the cross product F X r?

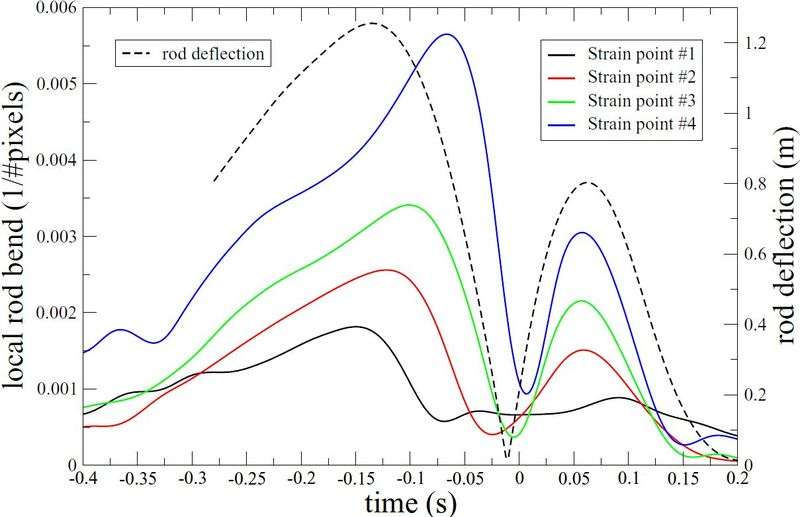

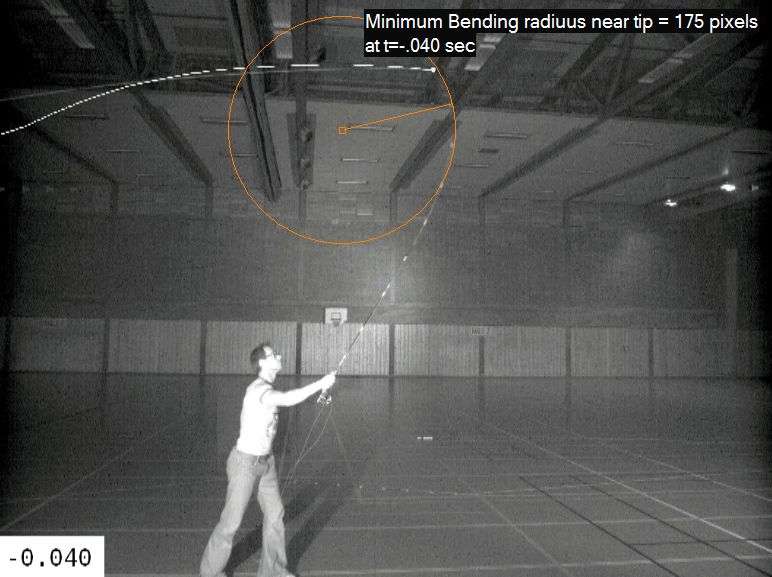

The breaking of spaghetti from stress resulting from the superposition of reflected waves was enlightening. Do you know what the propagation velocity of a flexural wave would be? I would expect they are much faster than the propagation of the maximum curvature point in the rod as it unloads that you measured below in your load shift curve. I will include that graph below so Merlin can see what you are talking about.

And here are a couple of overlays that show what the local rod bend measured as 1/(radius in pixels) represented.

I will see if I can get a .pdf copy of that paper from the Cal State library. If I can I will send you and Merlin the file. I expect that computing the propagation of flexural waves is going to be way above my abilities, but it will be interesting to see their analysis.

Gordy

"Flyfishing: 200 years of tradition unencumbered by progress." Ralph Cutter

Grunde

I have started checking the torque history during a cast with Gordy. I think now there can be a contribution from rod unloading to ease the beginning of deceleration, but not to the point that the rod can decelerate its rotation on its own. This phenomenon depends also on the timing fit between the loaded rod and the cast.

Such a consideration (rod decelerating its rotation speed on its own) does not hold the road on an energy standpoint. The kinetic energy of the rod shaft at maximum rotation speed is 4 to 5 times greater than the elastic energy stored into the rod at that same time. By consequence, there is no way an unloading rod can stop its rotation by itself (which Server Sadik states in his writings).

My next goal is to mimic the rebound that one can see on a casting analyser record. In that case, this rebound is due to the energy stored in the rod at counterflex.

Merlin

I have started checking the torque history during a cast with Gordy. I think now there can be a contribution from rod unloading to ease the beginning of deceleration, but not to the point that the rod can decelerate its rotation on its own. This phenomenon depends also on the timing fit between the loaded rod and the cast.

Such a consideration (rod decelerating its rotation speed on its own) does not hold the road on an energy standpoint. The kinetic energy of the rod shaft at maximum rotation speed is 4 to 5 times greater than the elastic energy stored into the rod at that same time. By consequence, there is no way an unloading rod can stop its rotation by itself (which Server Sadik states in his writings).

My next goal is to mimic the rebound that one can see on a casting analyser record. In that case, this rebound is due to the energy stored in the rod at counterflex.

Merlin

Fly rods are like women, they wont´play if they're maltreated.

Charles Ritz, A Flyfisher's Life

Charles Ritz, A Flyfisher's Life

- grunde

- Master of The Kettle

- Posts: 1462

- Joined: Thu Sep 09, 2004 5:48 pm

- Location: Drammen, Norway

- Contact:

For now I only have one short comment

For any elastic beam:

(E*I)/R = M

Where E is Youngs modulus, I is the area moment of inertia, R is the radii of curvature and M is the internal moment. At the boundary M = applied torque.

See for instance http://www.doitpoms.ac.uk/tlplib/beam_bending/bend_moments.php

http://www.optics.arizona.edu/optomec....W11.pdf

Cheers,

Grunde

gordonjudd wrote:Grunde

I do not see the relationship you are seeing in how the bending stress in the rod is related to the torque being applied at the butt.

For any elastic beam:

(E*I)/R = M

Where E is Youngs modulus, I is the area moment of inertia, R is the radii of curvature and M is the internal moment. At the boundary M = applied torque.

See for instance http://www.doitpoms.ac.uk/tlplib/beam_bending/bend_moments.php

http://www.optics.arizona.edu/optomec....W11.pdf

Cheers,

Grunde

"Essentially, all models are wrong, but some are useful."

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

Who is online

Users browsing this forum: No registered users and 1 guest