PLEASE NOTE: This is the Archived Sexyloops Board from years 2004-2013.

Our active community is here: https://www.sexyloops.co.uk/theboard/

Our active community is here: https://www.sexyloops.co.uk/theboard/

“Personal Perfect Rod” Recipe - Taylor make your rods

Bill

First question: not really, but after all, anyone is free to use anything he believes in. (One line number difference is approximately 0.12 N/m, how can I find that on your graph?)

Second question: I gave you some figures (3.6 cpm to 5.4 cpm) which means that your approach is not precise enough if you want to close a 2 cpm gap.

CSS does the same. May I suggest a quick and short procedure to “tune” your blanks without a chart? If you start from ERN 7 and want to go to ERN 5, just add the difference in weight corresponding to the line number (2.9 grams here) with your feel fixer. A simple approximation which Joe can understand.

Merlin

Now, all I am asking you engineers is: Will this chart be of value to such a rod builder, and what is a typical magnitude of error (in cpm) to be expected if it is used?”

First question: not really, but after all, anyone is free to use anything he believes in. (One line number difference is approximately 0.12 N/m, how can I find that on your graph?)

Second question: I gave you some figures (3.6 cpm to 5.4 cpm) which means that your approach is not precise enough if you want to close a 2 cpm gap.

That is the reason the CCS is so useful. It allows one to know the properties of any rod without actually seeing it. Knowing these properties allows the experienced angler to immediately ascertain its usefulness for his own or any other purposes.

CSS does the same. May I suggest a quick and short procedure to “tune” your blanks without a chart? If you start from ERN 7 and want to go to ERN 5, just add the difference in weight corresponding to the line number (2.9 grams here) with your feel fixer. A simple approximation which Joe can understand.

Merlin

Fly rods are like women, they wont´play if they're maltreated.

Charles Ritz, A Flyfisher's Life

Charles Ritz, A Flyfisher's Life

- Paul Arden

- Fly God 2010

- Posts: 23925

- Joined: Sat Jul 26, 2003 10:35 am

- Location: Travelling

- Contact:

I would wager not one angler in a million knows what that particular job was when he bought his rod. Rods just aren’t sold with personal instructions from the designer. They are just sold because they feel good.

This is not true. We have saltwater rods, we have stillwater rods, we have rods designed for salmon fishing with long lines, salmon rods designed for casting shooting heads, European nymphing rods, bass rods, rods designed for fishing sunk lines over the front of the boat, others designed for chucking leadcore, rods designed for tournament casting and so on and so on.

I doubt there's a million flyfishers in Europe, but I suspect that virtually all of them would know that a 7ft #3 was designed for fishing small streams, and not for tarpon.

Interesting thread by the way!

Cheers, Paul

-

Bill Hanneman

- IB3 Member Level 1

- Posts: 710

- Joined: Thu Oct 28, 2004 12:54 am

- Contact:

Merlin,

There is no way you can find it because such dimensions are not on that chart. The question is, “How many anglers know what 0.12 N/m means or would be remotely interested in finding it on any chart?

Thank you very much. I suspect you are the only one reading this thread who could have answered that question. Now, let’s calculate, 5.4 - 3.6 = 1.8 or 1.8/2 = 0.9. Then, can I conclude my estimate could be less than +/- 1 cpm in error? I would think that was pretty damn good for a first approximation—even if it were 2.

Congratulations, it just proves there is more than one way to skin a cat.

I see you have completely grasped the principle of the feel fixer. But, of course, we both know that value should be zero, so one preferably changes the line. So, how does the CSS calculate this in the absence of defined values of ERN and ELN? In other words, what power does your #5 rod have?

-----------------------------------------------------

------------------

Paul,

Let me introduce you to the real world of custom rod building. At each annual International Custom Rod Building Exposition, one of the major attractions and drawing features is the fact several major suppliers of fishing rod blanks use this venue to dispose of their “less popular” products. Consequently, one finds numerous garbage cans, each filled with miscellaneous rods of all types and none bearing any information about who, where, or why they were built. Use of the CCS allows any purchaser to easily determine the power, action, and frequency of any of those rods. With that knowledge any competent builder can determine the suitability of any rod for any purpose.

Q. Now, all I am asking you engineers is: Will this chart be of value to such a rod builder,

A. First question: not really, but after all, anyone is free to use anything he believes in. (One line number difference is approximately 0.12 N/m, how can I find that on your graph?)

There is no way you can find it because such dimensions are not on that chart. The question is, “How many anglers know what 0.12 N/m means or would be remotely interested in finding it on any chart?

Q. and what is a typical magnitude of error (in cpm) to be expected if it is used?”

A. Second question: I gave you some figures (3.6 cpm to 5.4 cpm) which means that your approach is not precise enough if you want to close a 2 cpm gap.

Thank you very much. I suspect you are the only one reading this thread who could have answered that question. Now, let’s calculate, 5.4 - 3.6 = 1.8 or 1.8/2 = 0.9. Then, can I conclude my estimate could be less than +/- 1 cpm in error? I would think that was pretty damn good for a first approximation—even if it were 2.

That is the reason the CCS is so useful. It allows one to know the properties of any rod without actually seeing it. Knowing these properties allows the experienced angler to immediately ascertain its usefulness for his own or any other purposes.

CSS does the same.

Congratulations, it just proves there is more than one way to skin a cat.

May I suggest a quick and short procedure to “tune” your blanks without a chart? If you start from ERN 7 and want to go to ERN 5, just add the difference in weight corresponding to the line number (2.9 grams here) with your feel fixer. A simple approximation which Joe can understand.

I see you have completely grasped the principle of the feel fixer. But, of course, we both know that value should be zero, so one preferably changes the line. So, how does the CSS calculate this in the absence of defined values of ERN and ELN? In other words, what power does your #5 rod have?

-----------------------------------------------------

------------------

Paul,

This is not true. We have saltwater rods, we have stillwater rods, we have rods designed for salmon fishing with long lines, salmon rods designed for casting shooting heads, European nymphing rods, bass rods, rods designed for fishing sunk lines over the front of the boat, others designed for chucking leadcore, rods designed for tournament casting and so on and so on.

Let me introduce you to the real world of custom rod building. At each annual International Custom Rod Building Exposition, one of the major attractions and drawing features is the fact several major suppliers of fishing rod blanks use this venue to dispose of their “less popular” products. Consequently, one finds numerous garbage cans, each filled with miscellaneous rods of all types and none bearing any information about who, where, or why they were built. Use of the CCS allows any purchaser to easily determine the power, action, and frequency of any of those rods. With that knowledge any competent builder can determine the suitability of any rod for any purpose.

Bill

Oh yes, I can. Gordy plotted curves every 0.1 N/m This is not so far from 0.12 N/m, but this shows you do not know where you are for a rod in the chart. 1 N/m is not so far from 9 feet #6. How did I get the 0.12 N/m? Simple: let’s assume our 906 is exactly at 1 N/m, the 905 will be at 1*9.1/10.4 = 0.875 N/m (0.9 on your chart if I follow the second step of the procedure. 0.12 is an average for trout rods of various length and line size. For a number 1, the stiffness would be 1 * 3.9 /10.4 = 0.375 N/m, while on your chart, it is 0.5 N/m. This last figure would correspond exactly to a #2 rod, and not a #1. So where are you?

You are smart for twisting numbers. I started again a calculation in your domain (mo = 2 to 2.5 grams, this corresponds to your spinning rod blanks likely) and looked after the amplitude of error you can make (do not divide again by 2, it has already been done): 3.6 cpm. This means that you cannot detect a difference which is smaller than that with the charts. So don’t think about 1 or 2.

I just need K and mo, and my own stiffness scale, which is easy to build. First, stiffness must be proportional to line weight. Second, since we refer to the relative deflection of a rod for a given for a given line number, it is conversely proportional to its length: the shorter, the stiffer.

Take the 906 at 1 N/m, you can get the stiffness for any line weight by calculating 1 * new line weight / 10.4 (a #6 is 10.4 grams). For a 905, it is 0.875 N/m.

If I want to know the stiffness for a 8 foot: same principle: new stiffness = 1 * 9 feet / new length, so it is 1.125 for a 806.

I can built as many stiffness scales I need from this simple formula. The one I give here could be close to your ERN.

Merlin

There is no way you can find it because such dimensions are not on that chart. The question is, “How many anglers know what 0.12 N/m means or would be remotely interested in finding it on any chart?

Oh yes, I can. Gordy plotted curves every 0.1 N/m This is not so far from 0.12 N/m, but this shows you do not know where you are for a rod in the chart. 1 N/m is not so far from 9 feet #6. How did I get the 0.12 N/m? Simple: let’s assume our 906 is exactly at 1 N/m, the 905 will be at 1*9.1/10.4 = 0.875 N/m (0.9 on your chart if I follow the second step of the procedure. 0.12 is an average for trout rods of various length and line size. For a number 1, the stiffness would be 1 * 3.9 /10.4 = 0.375 N/m, while on your chart, it is 0.5 N/m. This last figure would correspond exactly to a #2 rod, and not a #1. So where are you?

Thank you very much. I suspect you are the only one reading this thread who could have answered that question. Now, let’s calculate, 5.4 - 3.6 = 1.8 or 1.8/2 = 0.9. Then, can I conclude my estimate could be less than +/- 1 cpm in error? I would think that was pretty damn good for a first approximation—even if it were 2.

You are smart for twisting numbers. I started again a calculation in your domain (mo = 2 to 2.5 grams, this corresponds to your spinning rod blanks likely) and looked after the amplitude of error you can make (do not divide again by 2, it has already been done): 3.6 cpm. This means that you cannot detect a difference which is smaller than that with the charts. So don’t think about 1 or 2.

CSS calculate this in the absence of defined values of ERN and ELN? In other words, what power does your #5 rod have?

I just need K and mo, and my own stiffness scale, which is easy to build. First, stiffness must be proportional to line weight. Second, since we refer to the relative deflection of a rod for a given for a given line number, it is conversely proportional to its length: the shorter, the stiffer.

Take the 906 at 1 N/m, you can get the stiffness for any line weight by calculating 1 * new line weight / 10.4 (a #6 is 10.4 grams). For a 905, it is 0.875 N/m.

If I want to know the stiffness for a 8 foot: same principle: new stiffness = 1 * 9 feet / new length, so it is 1.125 for a 806.

I can built as many stiffness scales I need from this simple formula. The one I give here could be close to your ERN.

Merlin

Fly rods are like women, they wont´play if they're maltreated.

Charles Ritz, A Flyfisher's Life

Charles Ritz, A Flyfisher's Life

-

gordonjudd

- IB3 Member Level 1

- Posts: 2214

- Joined: Mon Jul 10, 2006 12:14 am

- Location: California

- Contact:

First, stiffness must be proportional to line weight.

Merlin,

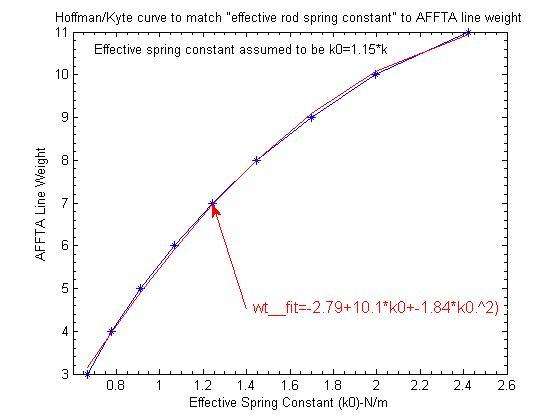

Here is Hoffman's curve for that relationship based on Al Kyte's preference for matching rod stiffness to a line wt that Al thought cast the best over a wide range of casting distances.

Hooper's method and line wt vs stiffness table was talked about

here.

You can see his curve takes the non-linear curve of line mass vs line weight into account.

The above curve is based on the measured spring constant value, and just as with the effective mass (m0) value is a scaled value relative to the total mass of the rod so is the effective spring constant a scaled value of the measured one. In one of my blanks I found the effective k0 value was 1.15 times higher than the measured k value. Using that scaling parameter (that may only be accurate for a full flex rod) you get this relationship between k0 and the AFFTA line number.

Gordy

"Flyfishing: 200 years of tradition unencumbered by progress." Ralph Cutter

Gordy

I use a simple linear scale because I use to estimate the stiffness of fly rods for small deflections. I wonder what this would give if I could estimate what the same scale looks like when the relative deflection is 25%, maybe it would come closer to this one, and turn out to be non linear. I checked on a couple of rods and I can confirm that for 0.25 relative deflection, the ratio in stiffness is less than the one for the linear estimation with small deflections..

I guess this curve has been established for a given rod length, otherwise, I am puzzled about designing a series of rods under these conditions. The problem behind is to ensure a constant relative deflection for a different length: it cannot correspond to the same stiffness, you know.

The fact that Hoffman's scale is non linear has some logic: it may be that a linear evolution would make the high line rods too fast to be used comfortably (the linear approximation gives higher stiffness, thus higher frequencies).

Merlin

I use a simple linear scale because I use to estimate the stiffness of fly rods for small deflections. I wonder what this would give if I could estimate what the same scale looks like when the relative deflection is 25%, maybe it would come closer to this one, and turn out to be non linear. I checked on a couple of rods and I can confirm that for 0.25 relative deflection, the ratio in stiffness is less than the one for the linear estimation with small deflections..

I guess this curve has been established for a given rod length, otherwise, I am puzzled about designing a series of rods under these conditions. The problem behind is to ensure a constant relative deflection for a different length: it cannot correspond to the same stiffness, you know.

The fact that Hoffman's scale is non linear has some logic: it may be that a linear evolution would make the high line rods too fast to be used comfortably (the linear approximation gives higher stiffness, thus higher frequencies).

Merlin

Fly rods are like women, they wont´play if they're maltreated.

Charles Ritz, A Flyfisher's Life

Charles Ritz, A Flyfisher's Life

-

gordonjudd

- IB3 Member Level 1

- Posts: 2214

- Joined: Mon Jul 10, 2006 12:14 am

- Location: California

- Contact:

The fact that Hoffman's scale is non linear has some logic:

Merlin,

I think his curve is non-linear because the AFFTA line weight vs mass curve is non-linear as you go to higher line weight values.

Also, this curve was based on Al Kyte's view of how a particular rod (they covered up the line designations on the rod so it was a blind study from Al's standpoint) was best matched to different line weights. Thus his view that a rod was 5.5 weight might have come out as being a 5 or a 6 if someone else was picking their preference.

You view and my view of what this curve would look like could well be different.

Remember that the line wt designations in the 15 deg method are about 1.5 line weights lower than the values determined in Bill's CCS system. Hoopers values are about .5 line weights lower than the CCS values.

That just shows there is no truly "objective" way to match a stiffness value to a line weight value, otherwise all three of these systems would come up with the same line number. In truth they just end up with a value that is based on the eye of the beholder who devised the rating system.

Gordy

"Flyfishing: 200 years of tradition unencumbered by progress." Ralph Cutter

-

Bill Hanneman

- IB3 Member Level 1

- Posts: 710

- Joined: Thu Oct 28, 2004 12:54 am

- Contact:

Merlin,

Now, I am completely lost and my eyes are beginning to glaze over, as are Joe’s and probably those of most of the lurkers here. There is no 0.5 N/m point on my chart because, as I previously said, there are no dimensions of that type on the chart.

What you have done, is to assume my chart correlates with Gordy’s and tested it on that assumption. A good assumption and from my point of view, a good conclusion. I won’t think about 1 or 2, as you say, but +/- 2 to 4 is still excellent for a first approximation. Thanks, again for your confirmation.

Fine, can you do that Joe? Or would you rather just hang a few weights on your rod tip and consult the ready-made Rosetta Stone?.

---------------------------

Fellows,

I believe this is all I have to say on this matter. I shall now bow out of this thread and leave the discussion of non linearity to others.

This non linearity is simply the result of an arbitrary decision of the AFTMA, who defined it.

Best wishes,

Bill

There is no way you can find it because such dimensions are not on that chart.

Oh yes, I can. ... For a number 1, the stiffness would be 1 * 3.9 /10.4 = 0.375 N/m, while on your chart, it is 0.5 N/m. This last figure would correspond exactly to a #2 rod, and not a #1. So where are you?

Now, I am completely lost and my eyes are beginning to glaze over, as are Joe’s and probably those of most of the lurkers here. There is no 0.5 N/m point on my chart because, as I previously said, there are no dimensions of that type on the chart.

What you have done, is to assume my chart correlates with Gordy’s and tested it on that assumption. A good assumption and from my point of view, a good conclusion. I won’t think about 1 or 2, as you say, but +/- 2 to 4 is still excellent for a first approximation. Thanks, again for your confirmation.

CSS calculate this in the absence of defined values of ERN and ELN? In other words, what power does your #5 rod have?

I just need K and mo, and my own stiffness scale, which is easy to build.

Fine, can you do that Joe? Or would you rather just hang a few weights on your rod tip and consult the ready-made Rosetta Stone?.

---------------------------

Fellows,

I believe this is all I have to say on this matter. I shall now bow out of this thread and leave the discussion of non linearity to others.

This non linearity is simply the result of an arbitrary decision of the AFTMA, who defined it.

Best wishes,

Bill

-

Bill Hanneman

- IB3 Member Level 1

- Posts: 710

- Joined: Thu Oct 28, 2004 12:54 am

- Contact:

- Paul Arden

- Fly God 2010

- Posts: 23925

- Joined: Sat Jul 26, 2003 10:35 am

- Location: Travelling

- Contact:

If there is non-linearity in the AFTMA system then how is it possible for ERN to work? As you go through the AFTMA table the difference between 3, 4, 5 and 6 weights is 20 grains per line weight. 6, 7 and 8 is 25 grains. 8 to 9 is 30 grains. 9 to 10 is 40 grains. 10, 11 and 12 is 50 grains.

It's made more complicated by the fact that 3 weights are designed to cast short distances, certainly less than a 10 yard carry, while your 9-12 weights in Saltwater are designed around longer than 10 yard carries.

I don't think you match a line weight only to rod stiffness, it's more complicated than that. Where I think CCS is useful is in comparing rod stiffness as a rough guide.

Cheers, Paul

It's made more complicated by the fact that 3 weights are designed to cast short distances, certainly less than a 10 yard carry, while your 9-12 weights in Saltwater are designed around longer than 10 yard carries.

I don't think you match a line weight only to rod stiffness, it's more complicated than that. Where I think CCS is useful is in comparing rod stiffness as a rough guide.

Cheers, Paul

-

Bill Hanneman

- IB3 Member Level 1

- Posts: 710

- Joined: Thu Oct 28, 2004 12:54 am

- Contact:

Bill,

Your ERN scale is OK for Joe (or the rodbuilder, sometime I am lost too). He has to find out the one that suits him best and avoid trying to make a fly rod from a spinning rod, if possible.

He may follow your chart or just use the difference in weight (which may include a different carry) in between the ERN of the blank and what he is looking for.

Hope the final result will suit his expectatiions.

Merlin

Your ERN scale is OK for Joe (or the rodbuilder, sometime I am lost too). He has to find out the one that suits him best and avoid trying to make a fly rod from a spinning rod, if possible.

He may follow your chart or just use the difference in weight (which may include a different carry) in between the ERN of the blank and what he is looking for.

Hope the final result will suit his expectatiions.

Merlin

Fly rods are like women, they wont´play if they're maltreated.

Charles Ritz, A Flyfisher's Life

Charles Ritz, A Flyfisher's Life

- Paul Arden

- Fly God 2010

- Posts: 23925

- Joined: Sat Jul 26, 2003 10:35 am

- Location: Travelling

- Contact:

I assume that by "rod builders" we mean those who finish rods and not those who design the blanks? I know quite a few designers and I know that they would have no trouble in determining which line they would like to cast on a given rod. They can all cast really well. Are you saying that rod builders who finish blanks, maybe cannot cast sufficiently well and are unhappy with the respective blank designer's intentions? I don't know of any examples of this relabelling in the commercial world - so I assume that the rod builders to which you refer are building rods for their own personal use? That is not exactly a mainstream purpose.

Where I do find CCS useful is for comparing various rod attributes and I think that's to be commended. The "Feel Fixer" however is very unfortunate.

Cheers, Paul

Where I do find CCS useful is for comparing various rod attributes and I think that's to be commended. The "Feel Fixer" however is very unfortunate.

Cheers, Paul

-

Bill Hanneman

- IB3 Member Level 1

- Posts: 710

- Joined: Thu Oct 28, 2004 12:54 am

- Contact:

Paul,

Yes indeed.

Casting ability has nothing to do with it. It is a function of one’s PPF, as Gordy noted below.

------------

No, I am saying not one builder or angler in one thousand actually knows what the intentions of the designer of any particular rod were—especially as to distance of cast. Rods and blank don’t normally come with instructions.

Commercial rod makers don’t have to as they use a meaningless notation to describe their products in the first place. They simply call an ERN 5.5 rod anything from a 3wt to a 7wt and visa versa, depending on what line they want to use and how far they want to cast—and independent of its actual power.

If you assume that, I must assume you have been living under a rock lately. There is considerable number of Custom Rod builders to whom the major manufacturers are happy to supply blanks.

Bill

I assume that by "rod builders" we mean those who finish rods and not those who design the blanks?

Yes indeed.

I know quite a few designers and I know that they would have no trouble in determining which line they would like to cast on a given rod. They can all cast really well.

Casting ability has nothing to do with it. It is a function of one’s PPF, as Gordy noted below.

“That just shows there is no truly "objective" way to match a stiffness value to a line weight value, otherwise all three of these systems would come up with the same line number. In truth they just end up with a value that is based on the eye of the beholder who devised the rating system.” (or designed the rod) (or is casting a rod) ...... "Shades of PPF."

------------

Are you saying that rod builders who finish blanks, maybe cannot cast sufficiently well and are unhappy with the respective blank designer's intentions?

No, I am saying not one builder or angler in one thousand actually knows what the intentions of the designer of any particular rod were—especially as to distance of cast. Rods and blank don’t normally come with instructions.

I don't know of any examples of this relabelling in the commercial world -

Commercial rod makers don’t have to as they use a meaningless notation to describe their products in the first place. They simply call an ERN 5.5 rod anything from a 3wt to a 7wt and visa versa, depending on what line they want to use and how far they want to cast—and independent of its actual power.

so I assume that the rod builders to which you refer are building rods for their own personal use? That is not exactly a mainstream purpose.

If you assume that, I must assume you have been living under a rock lately. There is considerable number of Custom Rod builders to whom the major manufacturers are happy to supply blanks.

Bill

Who is online

Users browsing this forum: No registered users and 0 guests