PLEASE NOTE: This is the Archived Sexyloops Board from years 2004-2013.

Our active community is here: https://www.sexyloops.co.uk/theboard/

Our active community is here: https://www.sexyloops.co.uk/theboard/

Harmonic Oscillator

-

gordonjudd

- IB3 Member Level 1

- Posts: 2214

- Joined: Mon Jul 10, 2006 12:14 am

- Location: California

- Contact:

Where E is Young's modulus, I is the area moment of inertia, R is the radii of curvature and M is the internal moment. At the boundary M = applied torque.

Grunde,

In that static case isn't the moment at the clamped end of the rod resulting from the tip load and the shortened length of the curved beam, not by a a torque that is applied at the clamped end of the beam?

I don't see how the bending moment in that static case corresponds to the angular acceleration that would result from a torque applied to the rod that is allowed to rotate about some axis.

From your model, it would appear to me that if a constant torque was applied to the butt of a flexible rod with a fixed tip load and that torque was applied for a long time period the rod tip deflection would just oscillate (about the increasing angle where the butt was pointed if you ignore the bending caused by aerodynamic drag) at some loaded frequency.

Thus the output of a strain gauge (located somewhere near your strain point three) would just have a sinusoidal output that tracked the tip deflection. It would not have a constant value that corresponded to the magnitude of the torque being applied to the butt.

Thus in the dynamic case the bend near the butt would not give a measure of the torque driving the rotation of the flexible beam but would just give a measure of the varying tip deflection.

Gordy

"Flyfishing: 200 years of tradition unencumbered by progress." Ralph Cutter

-

Eugene Moore

- IB3 Member Level 1

- Posts: 93

- Joined: Wed Jul 06, 2011 1:27 am

- Location: Missouri

- Contact:

Gordon,

You are correct if the torque is applied against a fixed load.

If the torque is applied against a free body this will create a rotation against the MOI of the blank. If the torque is applied over time this will create a constant acceleration of the blank against the MOI creating a constant deflection of the beam proportional to the acceleration. Velocity will continue to increase until the torque is removed at which time deflection will go to zero with velocity remaining constant. A decelerating torque will reverse the direction of deflection and reduce the velocity.

You are correct if the torque is applied against a fixed load.

If the torque is applied against a free body this will create a rotation against the MOI of the blank. If the torque is applied over time this will create a constant acceleration of the blank against the MOI creating a constant deflection of the beam proportional to the acceleration. Velocity will continue to increase until the torque is removed at which time deflection will go to zero with velocity remaining constant. A decelerating torque will reverse the direction of deflection and reduce the velocity.

Eugene Moore

- grunde

- Master of The Kettle

- Posts: 1462

- Joined: Thu Sep 09, 2004 5:48 pm

- Location: Drammen, Norway

- Contact:

gordonjudd wrote:Where E is Young's modulus, I is the area moment of inertia, R is the radii of curvature and M is the internal moment. At the boundary M = applied torque.

Grunde,

In that static case isn't the moment at the clamped end of the rod resulting from the tip load and the shortened length of the curved beam, not by a a torque that is applied at the clamped end of the beam?

In the static case the torque at the clamped end will have to match the torque caused by the load at the tip and the weight of the beam. And this clamped torque will be exactly equal to the internal moment M at the clamped end...

I don't see how the bending moment in that static case corresponds to the angular acceleration that would result from a torque applied to the rod that is allowed to rotate about some axis.

The bending moment is torque! The relation between local bend and local moment (the equation in my previous post), is as valid for both static and dynamical systems.

From the PRL on the breaking spaghetti problem: "the curvature is proportional to the internal moment, even in the dynamic theory of rods"

From your model, it would appear to me that if a constant torque was applied to the butt of a flexible rod with a fixed tip load and that torque was applied for a long time period the rod tip deflection would just oscillate (about the increasing angle where the butt was pointed if you ignore the bending caused by aerodynamic drag) at some loaded frequency.

Thus the output of a strain gauge (located somewhere near your strain point three) would just have a sinusoidal output that tracked the tip deflection. It would not have a constant value that corresponded to the magnitude of the torque being applied to the butt.

Thus in the dynamic case the bend near the butt would not give a measure of the torque driving the rotation of the flexible beam but would just give a measure of the varying tip deflection.

If a constant torque was applied to the butt the bend and thus the curvature at the butt would simply remain constant (the angular acceleration on the other hand would not have been constant). For a flexible rod/beam applying constant torque is not the same as applying constant angular acceleration. (You have the the same effect in the BSC-model where a constant acceleration of the car give a varying spring force.)

Cheers,

Grunde

"Essentially, all models are wrong, but some are useful."

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

- grunde

- Master of The Kettle

- Posts: 1462

- Joined: Thu Sep 09, 2004 5:48 pm

- Location: Drammen, Norway

- Contact:

Merlin wrote:Grunde

You cannot be serious (John Mc Enroe)?

???

Was the ball inn or out?

Of course I'm serious, how can the torque at the butt of the rod be different from the internal moment in the rod at the butt?

Any opinion on the energy standpoint?

Merlin

I have not seen your energy calculations so it's a bit hard to have much of a standpoint. But I can give you my own handwaving arguments:

If we compare the energy of the rod at MAV and when it comes to rest after returning from counter-flex (RSP2) we know that: The total energy of the rod at MAV will have to match: The work done by the rod on the fly line (between MAV and RSP) + The work done by the caster (against the motion of the rod between MAV and RSP2) + Dissipation (air drag)

Lets quickly run through the numbers for an example cast: 10m of #5 line (~10 g), at MAV 1 m deflection (spring constant 1 N/m), angular velocity 300 deg/s, line speed 18 m/s, MOI 65 g m^2 and chord length 2 m. At RSP the line speed is 22 m/s...

Total rod energy at MAV:

E_pot = 1/2 * k * x^2 = 0.5 J

E_kin = 1/2 * MOI * w^2 = 0.9 J (w = 300 * (2*pi/360) and MOI = 65/1000 kg m^2)

But since the rod is bent this kinetic energy is over estimated, we can correct for this by using the fact that MOI ~ l^2 (where l is the length of the rod). We thus estimate the corrected MOI' = (l_chord^2/l_rod^2) * MOI = (2.0/2.72)^2 * MOI=.54*65 = 35 g m^2

So the estimate for the corrected E_kin' = 0.5 J

So the 3 work components above will be ~ 1 J

At RSP the line speed is 22 m/s. The work on the line (W_line) will thus be at least the change in kinetic energy of the line (ignoring air drag on the line).

W_line = 1/2 * 10 * 10^-3 * (22^2 - 18^2) J = 0.8 J

So ~80% of the rod energy at MAV goes into the line...

It's early in the morning and I might have done a mistake or two, but if I'm in the right ballpark the reverse torque needed to stop (and damp) the rod will not be very large (~40 deg rotation from MAV to RSP2) and dissipation is high since the tip speed is at it's highest around RSP....

:pirate

Cheers,

Grunde

"Essentially, all models are wrong, but some are useful."

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

-

gordonjudd

- IB3 Member Level 1

- Posts: 2214

- Joined: Mon Jul 10, 2006 12:14 am

- Location: California

- Contact:

But since the rod is bent this kinetic energy is over estimated, we can correct for this by using the fact that MOI ~ l^2 (where l is the length of the rod). We thus estimate the corrected MOI' = (l_chord^2/l_rod^2) * MOI = 0.54 * MOI = 35 g m^2

Grunde,

I am glad that we can look at this from an energy standpoint, as I am not understanding the relationship of the applied torque and the angular acceleration of the butt of a flexible rod.

Using your model that is equivalent to a stiff rotating beam with a massless spring attached to a point mass can we assume that the torque applied at the butt has one component that is required to accelerate the MOI of the rod, and another that depends on the f x r moment to accelerate the mass with deflection force from the spring?

I would think the bend in the rod that is related to that f x r moment would be what you would measure with a strain gauge. I still do not see how the stain gauge value is going to measure the torque that is being applied to rotate the stiff butt of the rod.

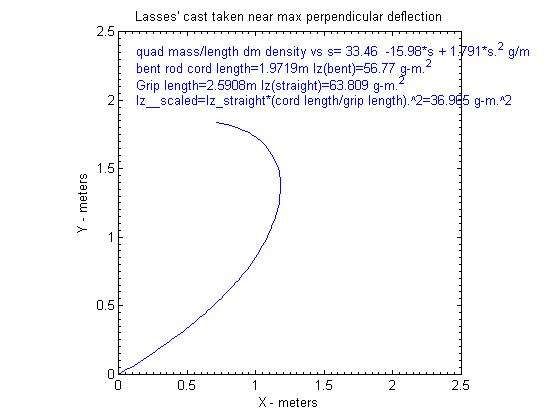

I have calculated the MOI of a bent rod and found that at least in the case of one of Lasse's casts, the MOI of the bent rod is larger than the ratio of the relative cord lengths squared. I calculated the MOI of the bent rod was about 56.8/63.8= 89% of its straight value as shown below. That is quite a bit larger than the (37.0/63.8) =58% relative MOI you get from the square of the relative cord lengths as noted in the comments on the graph below.

That means your corrected E_kin at MAV would be around .8 J. At RSP a flexible rod will have some K.E. as well as discussed here. and that K.E. can be estimated by the m0 value. In your example if the m0 was .003 Kg then the K.E. in the rod would be .5*.003*22^2 which would be .7 J.

The caster does more work on the line than you get from just the P.E. in the rod since the rod tip moves over a larger distance going from MAV to RSP1 as compared to the deflection distance, as you have calculated in the car/spring/brick model. Thus the K.E. gained by the line in going from MAV to RSP1 is going to be larger than than the P.E. change in the the rod.

I don't know how to estimate the portion of the rod's K.E. at MAV that goes into added K.E. of the line, but just based on the m0 and m_line values the rod's K.E. at RSP1 it will still have about 30% of the line's K.E. that has to be damped during counterflex.

Gordy

"Flyfishing: 200 years of tradition unencumbered by progress." Ralph Cutter

Grunde

I confirm Gordy's figure. I checked for several rods with a relative deflection around 50% and the MOI is about 90% to 95% of the MOI for the straight rod. That depends on its type of deflection (tip or butt). Thus the kinetic energy of the rotated rod is on the high side by comparison to the elastic energy stored at max deflection.

I shall post something with Gordy's help about torque during a cast. I need to make that not too much complicate, but I think one will see what is going on with the model.

So, it's on the line!

Merlin

I confirm Gordy's figure. I checked for several rods with a relative deflection around 50% and the MOI is about 90% to 95% of the MOI for the straight rod. That depends on its type of deflection (tip or butt). Thus the kinetic energy of the rotated rod is on the high side by comparison to the elastic energy stored at max deflection.

I shall post something with Gordy's help about torque during a cast. I need to make that not too much complicate, but I think one will see what is going on with the model.

So, it's on the line!

Merlin

Fly rods are like women, they wont´play if they're maltreated.

Charles Ritz, A Flyfisher's Life

Charles Ritz, A Flyfisher's Life

- grunde

- Master of The Kettle

- Posts: 1462

- Joined: Thu Sep 09, 2004 5:48 pm

- Location: Drammen, Norway

- Contact:

Merlin:

In this "torque during unload" discussion my point have been that it's simply not correct to assume:

T = a * MOI

where T is the torque from the caster on the rod butt, a is the angular acceleration measured at the rod butt and MOI is the moment of inertia of the rod. During the unload it's simply not correct to treat the rod as a rigid body with a point mass attached to a spring at the tip of the rigid rod. If I understand your (and Gordys) writings correctly, this erroneous "rigid body" assumption is what's causing the way to high stopping torques we have seen in some of the posted torque curves and comments (I've seen 80 to 100 N m :O ).

In short, I have never believed it's possible to go from full thrust forward to even fuller thrust backwards more or less instantaneously. And this lead me to point out that a backward torque at the butt should be visible as backwards bend, and there is no maximum backward bend during the unload. (In your graph I even see a peak forward torque during counterflex, where the rod bend tell us that we indeed have a backwards torque.)

So no, I (and I guess nor have Server) have never said that:

It's just that "its rotation" speed is not a single value (the angular velocity of the butt). And the rod-rotation is not at all stopped at RSP.

Later I said as a response to one of Gordys comment:

And your reply is:

So Merlin: Do you think that the torque at the butt of the rod is different from the internal moment in the elastic rod at the butt? If yes, you'll have to explain...

In addition I did give you my work-energy argument. Which (despite the fact that I overestimated the MOI reduction due to flex) show that

is clearly not the case...

I still see nothing in my work-energy argument which will dictate a large reverse (stopping)torque during unload. Damping of the rod (which is taking kinetic energy out of the rod) mainly happens during counterflex (where rod butt rotation and torque have opposite directions).

And for "normal casts", one will not have larger (reverse) torques during unload than the positive torques during the loading phase (from the start of the stroke and up to MAV). Just look at the bend...

It's a flexible lever, not a rigid body with a spring at the tip.

Cheers,

Grunde

In this "torque during unload" discussion my point have been that it's simply not correct to assume:

T = a * MOI

where T is the torque from the caster on the rod butt, a is the angular acceleration measured at the rod butt and MOI is the moment of inertia of the rod. During the unload it's simply not correct to treat the rod as a rigid body with a point mass attached to a spring at the tip of the rigid rod. If I understand your (and Gordys) writings correctly, this erroneous "rigid body" assumption is what's causing the way to high stopping torques we have seen in some of the posted torque curves and comments (I've seen 80 to 100 N m :O ).

In short, I have never believed it's possible to go from full thrust forward to even fuller thrust backwards more or less instantaneously. And this lead me to point out that a backward torque at the butt should be visible as backwards bend, and there is no maximum backward bend during the unload. (In your graph I even see a peak forward torque during counterflex, where the rod bend tell us that we indeed have a backwards torque.)

grunde wrote: I (like Server Sadik) believe that (at least) the first part of the rapid decceleration is caused by the unloading rod, and not by an active stop by the caster.

So no, I (and I guess nor have Server) have never said that:

Merlin wrote: ... an unloading rod can stop its rotation by itself (which Server Sadik states in his writings).

It's just that "its rotation" speed is not a single value (the angular velocity of the butt). And the rod-rotation is not at all stopped at RSP.

Later I said as a response to one of Gordys comment:

grunde wrote:gordonjudd wrote:Grunde

I do not see the relationship you are seeing in how the bending stress in the rod is related to the torque being applied at the butt.

For any elastic beam:

(E*I)/R = M

Where E is Youngs modulus, I is the area moment of inertia, R is the radii of curvature and M is the internal moment. At the boundary M = applied torque.

See for instance http://www.doitpoms.ac.uk/tlplib/beam_bending/bend_moments.php

http://www.optics.arizona.edu/optomec....W11.pdf

And your reply is:

Merlin wrote:Grunde

You cannot be serious (John Mc Enroe)?

Any opinion on the energy standpoint?

Merlin

grunde wrote: Of course I'm serious, how can the torque at the butt of the rod be different from the internal moment in the rod at the butt?

So Merlin: Do you think that the torque at the butt of the rod is different from the internal moment in the elastic rod at the butt? If yes, you'll have to explain...

In addition I did give you my work-energy argument. Which (despite the fact that I overestimated the MOI reduction due to flex) show that

Merlin wrote: The kinetic energy of the rod shaft at maximum rotation speed is 4 to 5 times greater than the elastic energy stored into the rod at that same time.

is clearly not the case...

I still see nothing in my work-energy argument which will dictate a large reverse (stopping)torque during unload. Damping of the rod (which is taking kinetic energy out of the rod) mainly happens during counterflex (where rod butt rotation and torque have opposite directions).

And for "normal casts", one will not have larger (reverse) torques during unload than the positive torques during the loading phase (from the start of the stroke and up to MAV). Just look at the bend...

It's a flexible lever, not a rigid body with a spring at the tip.

Cheers,

Grunde

"Essentially, all models are wrong, but some are useful."

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

Grunde

Absolutely, this is what I am working on now because I also realized that the kinetic energy in the rod would just fit that situation at maximum rod bend, not before (tip rotates slower by comparison to butt), and not after (tip rotates faster). So 90% of MOI is a bit optimistic.

Maybe, if you can see it. It may well depends on its intensity (a few Nm, no more). It would be better to be able to model that to be convinced; at least this is what I would like to see by myself.

In the rod frame, this is the case. Now this frame rotates, the consequence is not obvious to me. I intend checking what the energy story of the whole system can tell. Energy story, power story, and then torque up to the point we stop the rotation. I am tempted to say that if I accelerate the frame, it is more than that, and that if I decelerate the frame it is less than that. The disturbing parameter is the kinetic energy of the rod, in other words how to model it correctly (see above).

I never said it is large, I do not think so, I try to estimate that, but I cannot imagine today that the unloading of the rod itself does better than helping us to decelerate. It does not decelerate the rod for us, we do reduce the rotation speed.

In my graph? Which one? We never get in touch directly, Grunde, you know my mail address, but I do not know yours. What you have seen is a draft document which I wanted to test to find out inconsistencies from my modeling. I never posted it for that reason. My goal is just to end up with a fair modeling of what is going on and share it with the forum. This phenomenon you talk about, which could well be due to a lacking element in the energy story, just inspired me a thought about being a possible cause for the rebound we can see on casting analyzers records. This is just something to clarify and work on, not a final statement from my part. Here you seem using it to imply that I am all wrong because of this document (that could well be the case at the end, indeed, speaking about this draft).

I can draw two opposite conclusions from this last point:

• The good side: do not hesitate to criticize me directly; using my mail address, I can share anything on this subject with you. That will save some useless posts on the forum.

• The bad side: I am disappointed to learn that you got something that I could not send to you, without being informed before.

Looking forward reading some mail from you sometime.

Merlin

During the unload it's simply not correct to treat the rod as a rigid body with a point mass attached to a spring at the tip of the rigid rod. It's a flexible lever, not a rigid body with a spring at the tip.

Absolutely, this is what I am working on now because I also realized that the kinetic energy in the rod would just fit that situation at maximum rod bend, not before (tip rotates slower by comparison to butt), and not after (tip rotates faster). So 90% of MOI is a bit optimistic.

And this lead me to point out that a backward torque at the butt should be visible as backwards bend, and there is no maximum backward bend during the unload

Maybe, if you can see it. It may well depends on its intensity (a few Nm, no more). It would be better to be able to model that to be convinced; at least this is what I would like to see by myself.

Do you think that the torque at the butt of the rod is different from the internal moment in the elastic rod at the butt? If yes, you'll have to explain...

In the rod frame, this is the case. Now this frame rotates, the consequence is not obvious to me. I intend checking what the energy story of the whole system can tell. Energy story, power story, and then torque up to the point we stop the rotation. I am tempted to say that if I accelerate the frame, it is more than that, and that if I decelerate the frame it is less than that. The disturbing parameter is the kinetic energy of the rod, in other words how to model it correctly (see above).

I still see nothing in my work-energy argument which will dictate a large reverse (stopping) torque during unload.

I never said it is large, I do not think so, I try to estimate that, but I cannot imagine today that the unloading of the rod itself does better than helping us to decelerate. It does not decelerate the rod for us, we do reduce the rotation speed.

In your graph I even see a peak forward torque during counterflex, where the rod bend tell us that we indeed have a backwards torque

In my graph? Which one? We never get in touch directly, Grunde, you know my mail address, but I do not know yours. What you have seen is a draft document which I wanted to test to find out inconsistencies from my modeling. I never posted it for that reason. My goal is just to end up with a fair modeling of what is going on and share it with the forum. This phenomenon you talk about, which could well be due to a lacking element in the energy story, just inspired me a thought about being a possible cause for the rebound we can see on casting analyzers records. This is just something to clarify and work on, not a final statement from my part. Here you seem using it to imply that I am all wrong because of this document (that could well be the case at the end, indeed, speaking about this draft).

I can draw two opposite conclusions from this last point:

• The good side: do not hesitate to criticize me directly; using my mail address, I can share anything on this subject with you. That will save some useless posts on the forum.

• The bad side: I am disappointed to learn that you got something that I could not send to you, without being informed before.

Looking forward reading some mail from you sometime.

Merlin

Fly rods are like women, they wont´play if they're maltreated.

Charles Ritz, A Flyfisher's Life

Charles Ritz, A Flyfisher's Life

- grunde

- Master of The Kettle

- Posts: 1462

- Joined: Thu Sep 09, 2004 5:48 pm

- Location: Drammen, Norway

- Contact:

gordonjudd wrote:From my files, I can get an order of magnitude of the "braking torque" used to stop a rod. It is based on casts inspired from Paul's long distance casts, but let's see the order of magnitude in that extreme case: something between 80 an 100 N-m.

Merlin,

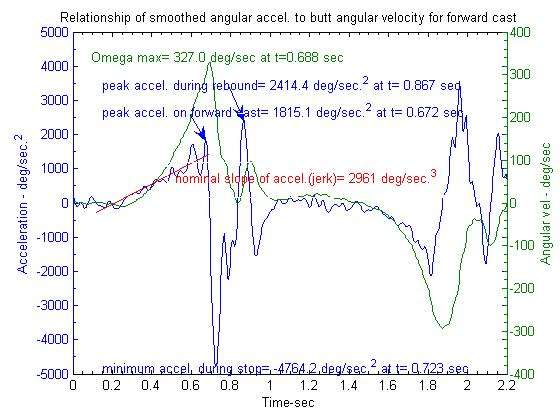

And just to show the difference for a less "heroic" cast with a much smaller deceleration factor here is the plot of the estimated torque applied to stop the rod using the data for the "Expert 50" casting analyzer file.

As shown below the maximum deceleration value for that cast was -4764 deg/sec.^2 (-83 radians/s.^2).

Assuming the MOI of the rod/reel/line system was .155 kg-m.^2 gives the estimated applied torque curve below.

That had a maximum reversing torque of -12.8 N-m so would require a force of 12.8/.4=32 N on the hand applied from the elbow. That is equivalent to holding a 3.2 Kg mass which is more in line with what you could expect for a non-distance cast.

Gordy

Posting from phone so this will be short.

I was not refering to anything you have done which have not been posted here...

Here are the graphs and large numbers I was refering to. I was under the impression that this was something you and Gordy was working on together?

And I agree, it's hard to measure small bends accuratly using image techniques, but using a strain gauge should be straightforward.

Cheers,

Grunde

"Essentially, all models are wrong, but some are useful."

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

Oooops! Sorry for misinterpreting your post, Grunde

My mood is quite pessimistic today, I should have a walk outside.

I forgot this picture which Gordy produced from a record I sent him I think. This translates into torque the rotation record of a casting analyzer. I was referring to something else, which looks somehow like that, if I can say so, but which comes from modeling.

I am reworking the model, and expect to send something to Gordy soon, and if you want to see that, just feel free to do so.

Merlin

My mood is quite pessimistic today, I should have a walk outside.

I forgot this picture which Gordy produced from a record I sent him I think. This translates into torque the rotation record of a casting analyzer. I was referring to something else, which looks somehow like that, if I can say so, but which comes from modeling.

I am reworking the model, and expect to send something to Gordy soon, and if you want to see that, just feel free to do so.

Merlin

Fly rods are like women, they wont´play if they're maltreated.

Charles Ritz, A Flyfisher's Life

Charles Ritz, A Flyfisher's Life

-

gordonjudd

- IB3 Member Level 1

- Posts: 2214

- Joined: Mon Jul 10, 2006 12:14 am

- Location: California

- Contact:

Here are the graphs and large numbers I was refering to. I was under the impression that this was something you and Gordy was working on together?

Grunde,

No, that misuse of using a rigid body mechanics was all my own doing. I don't know if Merlin did something different to come up with his original large torque values, but I thought a typical fishing cast would result in lower torque values than the 80 N-m values he derived for a distance cast.

I am still trying to understand how to modify the rigid body approach to take into account that all points on the rod are not rotating at the same rate and thus the use of KE=.5*MOI*ang_vel.^2 is not correct.

Could the actual KE in the rod be approximated by using a combination of the above equation with a .5*m0*spring_vel.^2 term to account for the added (or subtracted) portion of the rod that is moving relative to the motion of the rotating shadow beam?

I do want to understand how this should be done, and hope we can reach some valid conclusions that can be backed-up with energy (or power) considerations.

Gordy

"Flyfishing: 200 years of tradition unencumbered by progress." Ralph Cutter

- Hal Jordan

- IB3 Member Level 1

- Posts: 604

- Joined: Thu May 05, 2011 1:17 am

- Contact:

Grundegrunde wrote:In this "torque during unload" discussion my point have been that it's simply not correct to assume:

T = a * MOI

where T is the torque from the caster on the rod butt, a is the angular acceleration measured at the rod butt and MOI is the moment of inertia of the rod. During the unload it's simply not correct to treat the rod as a rigid body with a point mass attached to a spring at the tip of the rigid rod. If I understand your (and Gordys) writings correctly, this erroneous "rigid body" assumption is what's causing the way to high stopping torques we have seen in some of the posted torque curves and comments (I've seen 80 to 100 N m :O ).

In short, I have never believed it's possible to go from full thrust forward to even fuller thrust backwards more or less instantaneously. And this lead me to point out that a backward torque at the butt should be visible as backwards bend, and there is no maximum backward bend during the unload. (In your graph I even see a peak forward torque during counterflex, where the rod bend tell us that we indeed have a backwards torque.)

So no, I (and I guess nor have Server) have never said that:grunde wrote: I (like Server Sadik) believe that (at least) the first part of the rapid decceleration is caused by the unloading rod, and not by an active stop by the caster.Merlin wrote: ... an unloading rod can stop its rotation by itself (which Server Sadik states in his writings).

I'm glad to see that you and Server are thinking along similar lines because I've learned a lot from Server and I value your opinion a great deal as well.

I haven't heard Server say that the rod can stop itself but he does say it will unload without us having to physically stop the rod. I think that for the rod to completely stop itself there would have to be zero energy loss during the loading and unloading of the rod and we know that isn't realistic.

Gordy,

That's what I am doing as a first estimate, but I use the relative speed of the spring. During the loading, I subtract that quantity to take in account the relative lower speed of the tip, and I add it during the unloading, since the tip goes faster than the butt in that case.

Don't rely too much of my estimates with the model of Paul's cast, the energy story is not correct in that case (I shall rework it later).

Walter,

Who said "Fortunately, it can be easily shown that prior to RSP, the caster never exerts retarding moment/torques on the rod..."? "So the spring back of the rod has such a strong effect that it actually eliminates most of the angular velocity of the rod butt"!

Not me, for sure.

Merlin

Could the actual KE in the rod be approximated by using a combination of the above equation with a .5*m0*spring_vel.^2 term to account for the added (or subtracted) portion of the rod that is moving relative to the motion of the rotating shadow beam?

That's what I am doing as a first estimate, but I use the relative speed of the spring. During the loading, I subtract that quantity to take in account the relative lower speed of the tip, and I add it during the unloading, since the tip goes faster than the butt in that case.

Don't rely too much of my estimates with the model of Paul's cast, the energy story is not correct in that case (I shall rework it later).

Walter,

Who said "Fortunately, it can be easily shown that prior to RSP, the caster never exerts retarding moment/torques on the rod..."? "So the spring back of the rod has such a strong effect that it actually eliminates most of the angular velocity of the rod butt"!

Not me, for sure.

Merlin

Fly rods are like women, they wont´play if they're maltreated.

Charles Ritz, A Flyfisher's Life

Charles Ritz, A Flyfisher's Life

- grunde

- Master of The Kettle

- Posts: 1462

- Joined: Thu Sep 09, 2004 5:48 pm

- Location: Drammen, Norway

- Contact:

Merlin wrote:Who said "Fortunatly, it can be easily shown that prior to RSP, the caster never exerts retarding moment/torques on the rod..."? "So the spring back of the rod has such a strong effect that it actually eliminates most of the angular velocity of the rod butt"!

I have no big problem with any of these comments (except for the "easily shown", which is a common understatement in the literature)...

My wording would have been a bit different though, I think one should at least be a bit careful with never...

:pirate

Cheers,

Grunde

"Essentially, all models are wrong, but some are useful."

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

George E. P. Box

Always question the assumptions!

Flycasting Definitions

...

Who is online

Users browsing this forum: No registered users and 0 guests