FlyAlf wrote:" the ERN/AA data gives me a broad view of a rod, but not an idea of its performance." Disagree: The ERN (and AA) gives an idea of its performance. You would surely agree that to have some objective number of stiffness (even at one given load) would say something of its performance.

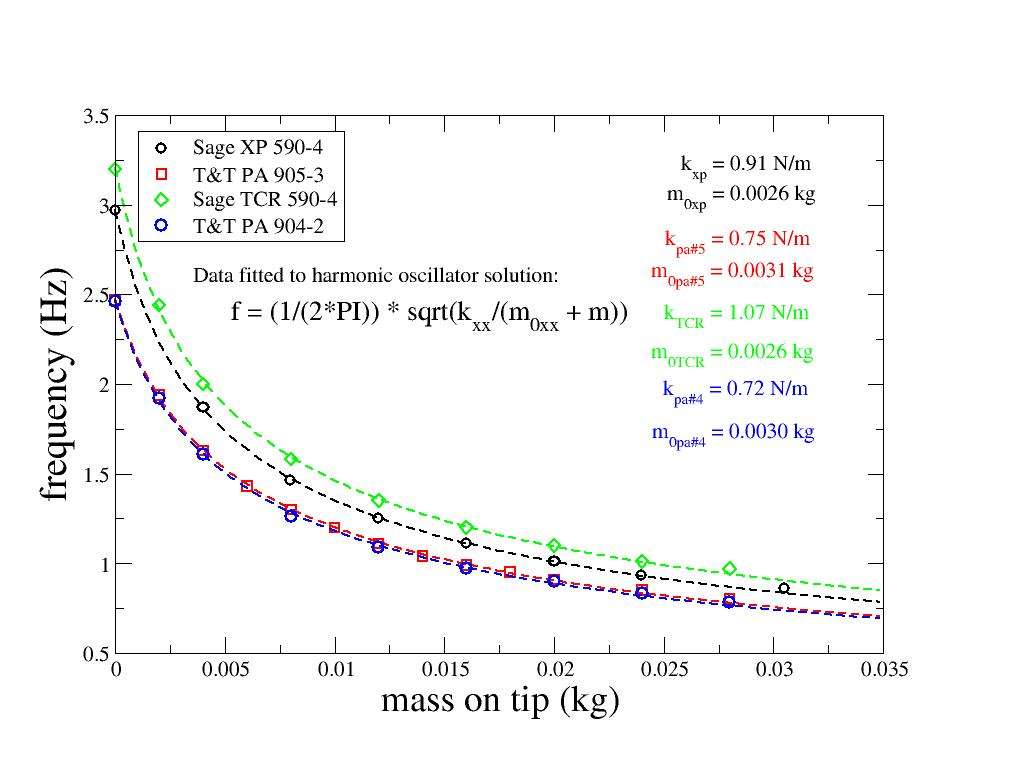

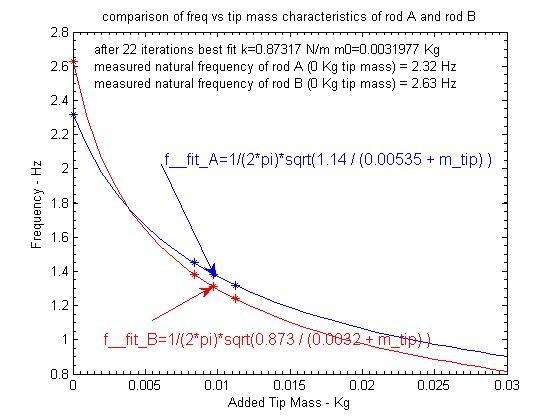

"This does not tell me how fast is the rod". To tell how fast you need to measure frequency.

"...and how it reacts to load" Disagree. This is exactly what ERN does. It says something about stiffness. But I agree that one normally uses such as spring constant to measure ... a spring. More correct would be to state "and how it reacts to different loads"?

Influence of mass?

"Change the mass of the blank using stiffer material but keeping stiffness the same, and you shall see that rod performance will completly change while ERN/AA are likely to remain the same." Yes, and? If the stiffness is the same, its the same

. If the AA is the same its the same

. So these two rods should in my not-so-humble opinion have the same action, and handle the same lines since they are equally stiff. They would not "perform" equally in the meaning of "feeling". To better understand this part of the "performance" I would measure the frequency.

"We use the rod dynamically but we like making static measurements (most rod companies do the same)"

Yes, because some understanding of the rod can be achieved by such static measurements. Its easy to do and understand, and for some it good enough. And most rod companies do not share even the basic static parameters with us. Instead the paint some meaningless arbitrary number on the rod indicating that all casters are the same as their test caster and prefer the same stiffness instead of trying to tell how stiff the rod is and letting us choose.

Dynamically versus static measurements?

Im not sure that I understand the difference clearly. If you by "dynamic" mean as a part of a caster-rod system we have other tools such as the caster analyzer.

If you by dynamic mean sampling over time then measurements of frequency is one such dynamic method.

If you mean how the rod reacts to different loads that is for me inherent by knowing the AA/ERN- AA tells me something about action, and ERN about stiffness.

I do look forward to better understand your purpose though.